Premier Aluminum Llc for Beginners

Premier Aluminum Llc for Beginners

Blog Article

The Of Premier Aluminum Llc

Table of ContentsGetting My Premier Aluminum Llc To WorkIndicators on Premier Aluminum Llc You Should KnowThe Single Strategy To Use For Premier Aluminum LlcGetting My Premier Aluminum Llc To WorkThe smart Trick of Premier Aluminum Llc That Nobody is Discussing

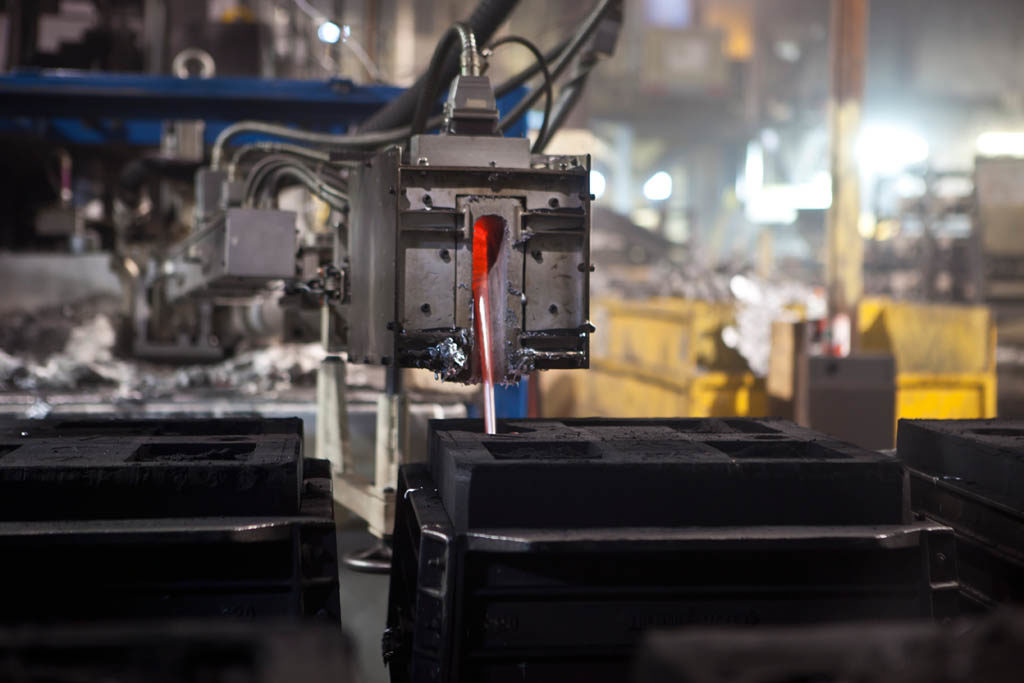

When selecting a light weight aluminum foundry for your manufacturing needs, it's important to study numerous factors. One of one of the most crucial elements to take into consideration is the experience and proficiency of the factory. Picking a foundry who has the ideal expertise of the aluminum casting process, and the portfolio to reveal for it, aids to have a successful end result for your project.Having the experience and market expertise to engineer your castings for ideal production and high quality end results will certainly streamline the job. Producing light weight aluminum castings needs a complicated collection of procedures to achieve the right results. When making a decision on a brand-new light weight aluminum shop to companion with, guarantee they have considerable sector experience and are educated concerning all facets of the light weight aluminum spreading procedure: design, production, product evaluation, and item screening.

The factory must likewise have a tested track record of providing exceptional items that satisfy or surpass client expectations. Quality control should also be at the top of your listing when picking a light weight aluminum factory. By dealing with a qualified shop who follows the standards for quality assurance, you can shield the integrity of your item and ensure it meets your specifications.

Premier Aluminum Llc - Truths

This specific process can be automated and repeated. Numerous parts that extremely complicated forms can be made using this process. Consequently, huge volumes of parts can be produced in simply a short amount of time. Before you begin browsing for a trustworthy aluminum pass away wheel, there are some essential points that you require to do first.

You have to ask yourself what type of aluminum pass away spreadings you call for. After determining what you need, you have to state the specs of the light weight aluminum pass away spreadings you require.

After having this details, you can begin researching light weight aluminum die-casting manufacturers. You can do this by simply typing the keyword phrase" Light weight aluminum die casting producers" on the Google search engine.

Several of the inquiries you require to ask on your own are whether they have actually experienced and trained operators, how much time their service has been in procedure, or if they have some accomplishments. You can commonly obtain the solution to these inquiries from the maker's internet site. You can research other websites or outside resources to verify if the information supplied on the manufacturer's website is genuine.

Getting My Premier Aluminum Llc To Work

An additional point you have to consider is the maker's capability to produce aluminum die-casting products. In other words, the quantity of items the manufacturer can produce at a provided time. Some of the critical inquiries you need to ask on your own are whether the maker can create a greater quantity or can the producer meet your demands.

(https://www.wattpad.com/user/premieraluminum)What happens if your company requires 10,000 pieces of certain machine components from the producer within one month? You got this quantity; nonetheless, the manufacturer can only generate 5000 items of these machine parts within one month (Foundry near me). Consequently, you won't have the ability to get the amount that you purchase on time

What Does Premier Aluminum Llc Mean?

Therefore, it is necessary that you need to inquire if the producer is carrying out an internal tooling procedure. Furthermore, you have to ask the manufacturer how much the expense of in-house tooling is. The in-house tooling procedure, which permits you to develop unique styles and shapes can be an additional expense.

This element directly associates with the manufacturer's production capacity. You need to try to find a producer that can guarantee quicker shipment of products. Nonetheless, this should be performed in such a means that high-grade criteria are preserved. This can ensure that you can obtain your items on schedule, and you can prevent missing out on those valuable organization opportunities.

This implies that there are numerous alternatives that you can pick from. Today, client demands keep on altering. It seems that customers are looking for a superb combination of top quality, cost-effectiveness, and resilience. That is why it is considerably suggested that you should pick a maker that can generate various sorts of light weight aluminum die-cast products.

The Definitive Guide for Premier Aluminum Llc

A lot of typically, these aluminum die-casting products will require some styles, machining, or finishing touches. Having this in mind, you ought to look for a supplier that can implement a range of second ending up works when die casting is done. read this post here Some examples of ending up procedures consist of Chromating, CNC Machining, Sandblasting, Powder layer, Anodized, E-coating, Damp paint, Plating, and lots of more.

Pass away casting is one of the most cost-efficient, exact, and protean manufacturing processes in the globe minute. The process entails suitable molten essence, under stress, right into an applicable die (earth), and previously strengthened it can be expelled and finished (if required) in a variety of methods. Report this page